The production of glass for skyscrapers involves several key players within the construction industry. Architectural glass manufacturers specialize in the engineering, design, and fabrication of glass facades for high-rise buildings. These companies collaborate closely with architects, engineers, and contractors to ensure the structural integrity, energy efficiency, and aesthetic appeal of the glass components.

The importance of glass in skyscrapers cannot be overstated. It provides natural light, reduces energy consumption, and enhances the overall design and functionality of the building. Advancements in glass technology have led to the development of innovative products such as low-emissivity glass, which reflects heat and improves insulation, and self-cleaning glass, which reduces maintenance costs.

The main article will delve deeper into the processes involved in glass production for skyscrapers, exploring the different types of glass used, the manufacturing techniques employed, and the latest innovations shaping this crucial aspect of modern architecture.

1. Manufacturers

Architectural glass manufacturers specializing in high-rise facades play a pivotal role in the production of glass for skyscrapers. These manufacturers possess the expertise, technology, and infrastructure to engineer, design, and fabricate glass facades that meet the unique demands of high-rise buildings. Their involvement is crucial to ensure the structural integrity, energy efficiency, and aesthetic appeal of the glass components.

High-rise facades require specialized glass that can withstand high winds, extreme temperatures, and seismic forces. Architectural glass manufacturers employ advanced production techniques and utilize high-quality materials to create glass that meets these stringent requirements. They collaborate closely with architects, engineers, and contractors throughout the design and construction process to ensure the glass facades seamlessly integrate with the overall building structure and design concept.

The expertise of architectural glass manufacturers is particularly evident in the development of innovative glass products tailored to the specific needs of skyscrapers. For instance, low-emissivity glass helps regulate temperature by reflecting heat, reducing energy consumption and improving occupant comfort. Self-cleaning glass minimizes the need for maintenance, enhancing the building’s long-term performance and aesthetics. These advancements demonstrate the ongoing commitment of architectural glass manufacturers to pushing the boundaries of glass technology and meeting the evolving demands of high-rise construction.

2. Architects

Architects play a critical role in the design and functionality of glass components for skyscrapers. They collaborate closely with architectural glass manufacturers to translate their design concepts into reality. Architects consider factors such as the building’s overall aesthetic, the desired natural light levels, and the structural requirements when specifying the type and properties of glass to be used.

The aesthetic vision of the architect guides the selection of glass that complements the building’s architectural style. Whether it’s a reflective glass facade that mirrors the surrounding cityscape or a tinted glass that creates a specific ambiance, the architect’s design intent is realized through the choice of glass. Additionally, architects work closely with engineers to ensure that the glass components meet the structural demands of the building, including wind resistance and seismic stability.

The practical significance of understanding the connection between architects and glass manufacturers lies in the ability to create high-performance, visually stunning glass facades for skyscrapers. Architects bring their creativity and design expertise to the table, while glass manufacturers provide the technical knowledge and manufacturing capabilities to bring those designs to life. This collaboration is essential for achieving the desired aesthetic, functionality, and performance of glass components in skyscrapers.

3. Engineers

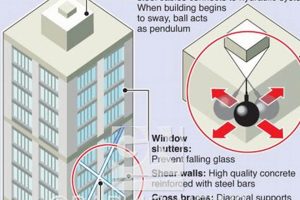

Engineers play a crucial role in the production of glass for skyscrapers as they are responsible for ensuring the structural integrity and energy efficiency of the glass components. Their expertise is vital in designing glass facades that can withstand the unique challenges of high-rise buildings, such as high winds, seismic forces, and thermal stresses.

To achieve structural integrity, engineers carefully calculate the loads and forces that the glass will be subjected to and design the glass components accordingly. They consider factors such as the height and shape of the building, the local climate, and the intended use of the space. Engineers also specify the type of glass to be used, taking into account its strength, durability, and optical properties.

In addition to structural integrity, engineers also focus on improving the energy efficiency of glass facades. They design glass components that minimize heat loss in cold climates and heat gain in warm climates, reducing the building’s energy consumption and carbon footprint. This is achieved through the use of energy-efficient glass coatings and insulating glass units.

The practical significance of understanding the connection between engineers and glass manufacturers lies in the ability to create high-performance, sustainable glass facades for skyscrapers. Engineers bring their technical expertise and analytical skills to the table, while glass manufacturers provide the manufacturing capabilities to bring those designs to life. This collaboration is essential for achieving the desired safety, efficiency, and performance of glass components in skyscrapers.

4. Contractors

In the intricate world of skyscraper construction, contractors play a pivotal role in the installation and maintenance of glass facades, forming an indispensable link between those who make glass for skyscrapers and the final realization of these architectural marvels.

- Skilled Craftsmanship and Precision Installation: Contractors possess the expertise and specialized skills to handle and install glass components with utmost precision, ensuring structural integrity and flawless aesthetics. Their meticulous attention to detail guarantees that each glass panel is securely fastened, aligned, and sealed, creating a weather-resistant and visually stunning facade.

Ongoing Maintenance and Inspection: The responsibilities of contractors extend beyond the initial installation, as they are tasked with the ongoing maintenance and inspection of glass facades. Regular cleaning, repairs, and replacements are essential to preserve the functionality and beauty of these architectural elements. Contractors conduct thorough inspections to identify any potential issues, ensuring the continued safety and performance of the glass facades. - Collaboration and Coordination: Contractors work closely with architects, engineers, and manufacturers throughout the project lifecycle, fostering effective communication and ensuring that the installation and maintenance of glass facades align seamlessly with the overall design and structural requirements of the skyscraper.

- Safety and Compliance: Contractors prioritize safety at every stage of their work, adhering to strict industry standards and regulations. They employ specialized equipment and techniques to minimize risks during installation and maintenance, ensuring the well-being of workers and the integrity of the building.

Contractors serve as the bridge between the creation and preservation of glass facades in skyscrapers. Their expertise, attention to detail, and commitment to quality ensure that these architectural wonders continue to soar high, reflecting both the ingenuity of their makers and the enduring beauty of human craftsmanship.

5. Technology

Technological advancements play a pivotal role in the production of glass for skyscrapers, enabling manufacturers to create high-performance, visually stunning, and sustainable glass facades. These advancements encompass both glass production techniques and coating technologies, each contributing to the exceptional qualities of skyscraper glass.

In glass production, float glass and laminated glass are two prominent techniques. Float glass involves floating molten glass on a bed of molten tin, resulting in a smooth, distortion-free surface ideal for large-scale architectural applications. Laminated glass, on the other hand, is created by bonding multiple glass panes with interlayers of plastic, enhancing the strength, safety, and sound insulation properties of the glass.

Coating technologies further enhance the functionality of glass for skyscrapers. Low-emissivity (low-e) coatings reduce heat transfer, improving energy efficiency and occupant comfort. Reflective coatings control solar heat gain, reducing glare and cooling loads. Self-cleaning coatings utilize hydrophilic and photocatalytic properties to minimize dirt accumulation, simplifying maintenance and preserving the aesthetic appeal of the glass facade.

The practical significance of understanding the connection between technology and glass production for skyscrapers lies in the ability to create high-performing, sustainable, and visually impactful glass facades. By leveraging advanced technologies, manufacturers can meet the unique demands of high-rise construction, pushing the boundaries of architectural design and engineering.

6. Materials

The types of glass used in skyscraper construction play a crucial role in determining the building’s energy efficiency, aesthetics, and overall performance. Architectural glass manufacturers offer a wide range of glass options, each with unique properties tailored to the specific requirements of high-rise structures.

- Low-Emissivity (Low-E) Glass:

Low-E glass is coated with a microscopically thin layer of metal or metal oxide, which reflects long-wave infrared radiation, effectively reducing heat transfer. This coating helps keep buildings warmer in winter and cooler in summer, leading to significant energy savings and improved occupant comfort. Low-E glass is widely used in skyscrapers to enhance energy efficiency and meet sustainability standards. - Self-Cleaning Glass:

Self-cleaning glass is coated with a hydrophilic and photocatalytic coating that breaks down organic dirt and debris when exposed to sunlight and rainwater. This advanced coating reduces the need for frequent cleaning, minimizing maintenance costs and preserving the aesthetic appeal of the glass facade. Self-cleaning glass is particularly beneficial for skyscrapers, as it ensures clear views and a pristine appearance even in challenging urban environments. - Laminated Glass:

Laminated glass is created by bonding two or more layers of glass with a plastic interlayer, typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). This construction provides enhanced strength, safety, and sound insulation. Laminated glass is commonly used in skyscraper facades to withstand high winds, impacts, and seismic forces, ensuring the safety of occupants and the integrity of the building. - Tinted Glass:

Tinted glass is manufactured by adding metal oxides or other coloring agents to the glass during production. This process results in glass with a specific color or shade, which can be used to control solar heat gain, reduce glare, and enhance the aesthetics of the building. Tinted glass is often employed in skyscrapers to create visually striking facades while managing the amount of natural light entering the building.

In summary, the types of glass used in skyscraper construction are carefully selected to meet the unique performance requirements of high-rise buildings. Low-E glass, self-cleaning glass, laminated glass, and tinted glass are just a few examples of the specialized glass products offered by architectural glass manufacturers, demonstrating the close connection between materials and the expertise of those who make glass for skyscrapers.

7. Innovation

Innovation in glass design and manufacturing plays a crucial role in shaping the capabilities of those who make glass for skyscrapers. Ongoing research and development efforts drive advancements in glass technology, leading to the creation of high-performance, sustainable, and visually stunning glass facades.

One significant area of innovation is the development of new glass compositions and coatings. Researchers are exploring the use of advanced materials, such as graphene and nano-engineered coatings, to enhance the strength, durability, and energy efficiency of glass. These advancements enable the production of glass that can withstand extreme weather conditions, reduce heat loss, and generate renewable energy, pushing the boundaries of architectural possibilities.

Another area of focus is the integration of smart technologies into glass facades. By embedding sensors and actuators into the glass, manufacturers can create responsive and interactive building envelopes that adapt to changing environmental conditions and user needs. Smart glass can automatically adjust its transparency, regulate temperature, and provide real-time data on energy consumption, contributing to the overall sustainability and efficiency of skyscrapers.

The practical significance of understanding the connection between innovation and glass production for skyscrapers lies in the ability to create buildings that are not only aesthetically pleasing but also environmentally responsible and te

chnologically advanced. By harnessing the latest innovations, manufacturers can meet the evolving demands of architects, engineers, and building owners, shaping the future of skyscraper design and construction.

Frequently Asked Questions about “Who Makes Glass for Skyscrapers”

This section addresses common concerns and misconceptions surrounding the production of glass for skyscrapers, providing concise and informative answers.

Question 1: Who are the primary manufacturers of glass for skyscrapers?

Architectural glass manufacturers specialize in the engineering, design, and fabrication of glass facades for high-rise buildings. These companies possess the expertise, technology, and infrastructure to produce high-performance glass that meets the unique demands of skyscrapers, such as structural integrity, energy efficiency, and aesthetic appeal.

Question 2: What types of glass are commonly used in skyscraper construction?

Architectural glass manufacturers offer a range of glass options tailored to the specific requirements of high-rise buildings. These include low-emissivity (low-e) glass for energy efficiency, self-cleaning glass for reduced maintenance, laminated glass for enhanced strength and safety, and tinted glass for solar heat control and aesthetic purposes.

Question 3: How do architects and engineers collaborate with glass manufacturers?

Architects and engineers work closely with glass manufacturers throughout the design and construction process to ensure that the glass facades seamlessly integrate with the overall building structure and design concept. Architects provide their creative vision and functional requirements, while engineers ensure the structural integrity and energy efficiency of the glass components.

Question 4: What advancements are being made in glass design and manufacturing for skyscrapers?

Ongoing research and development efforts are driving advancements in glass technology, leading to the creation of high-performance, sustainable, and visually stunning glass facades. Innovations include the use of advanced materials and coatings to enhance strength, durability, and energy efficiency, as well as the integration of smart technologies for responsive and interactive building envelopes.

Question 5: How does the use of glass impact the sustainability of skyscrapers?

Glass facades play a significant role in the sustainability of skyscrapers. Energy-efficient glass coatings can reduce heat transfer, lowering energy consumption and carbon emissions. Additionally, the use of recycled glass in manufacturing and the recyclability of glass at the end of a building’s life cycle contribute to sustainable construction practices.

Question 6: What factors should be considered when selecting glass for a skyscraper?

When selecting glass for a skyscraper, factors such as structural requirements, energy efficiency, natural light transmission, occupant comfort, aesthetics, and maintenance considerations should be taken into account. Architectural glass manufacturers can provide guidance and expertise to help architects, engineers, and building owners make informed decisions based on the specific needs of each project.

In conclusion, the production of glass for skyscrapers involves a collaborative effort among architectural glass manufacturers, architects, engineers, and contractors. Ongoing advancements in glass design and manufacturing are pushing the boundaries of architectural possibilities, creating high-performance, sustainable, and visually stunning glass facades for skyscrapers around the world.

Transition to the next article section: This section has addressed common questions about “who makes glass for skyscrapers.” The following section will delve deeper into the intricate details of glass production for these towering structures, exploring the processes, materials, and innovations involved.

Tips from the Experts

For those involved in the design, construction, or maintenance of skyscrapers, understanding the intricacies of glass selection and optimization is crucial. Here are some valuable tips from industry experts to ensure high-performance glass facades:

Tip 1: Prioritize Energy Efficiency: Opt for low-emissivity (low-e) glass coatings to minimize heat transfer and reduce energy consumption. Consider dynamic glazing systems that automatically adjust their transparency based on sunlight intensity, further enhancing energy savings.

Tip 2: Enhance Structural Integrity: Utilize laminated glass for increased strength and safety. Laminated glass comprises multiple layers bonded with interlayers, providing resistance to high winds, impacts, and seismic forces.

Tip 3: Maximize Natural Light Transmission: Select high-performance glass with excellent light transmittance to optimize natural daylighting. This reduces the reliance on artificial lighting, improves occupant well-being, and minimizes energy consumption.

Tip 4: Control Solar Heat Gain: Implement tinted or reflective glass coatings to regulate solar heat gain. This helps maintain comfortable indoor temperatures, reduces glare, and contributes to overall energy efficiency.

Tip 5: Minimize Maintenance Costs: Utilize self-cleaning glass coatings to reduce the need for frequent cleaning. These coatings break down dirt and debris, ensuring pristine glass facades and minimizing maintenance expenses.

Tip 6: Integrate Smart Technologies: Explore the integration of smart glass technologies, such as electrochromic glass that can adjust its transparency on demand. This provides enhanced control over natural light and privacy, contributing to occupant comfort and energy efficiency.

Tip 7: Consider Environmental Impact: Choose glass manufactured with recycled content and ensure the recyclability of glass at the end of its life cycle. This promotes sustainable construction practices and reduces environmental impact.

Tip 8: Collaborate with Experts: Partner with reputable architectural glass manufacturers and glazing contractors. Their expertise can guide you in selecting the optimal glass solutions that meet your specific project requirements.

By implementing these tips, professionals in the skyscraper industry can harness the full potential of glass facades, ensuring high performance, sustainability, and occupant well-being in these towering structures.

Transition to the conclusion: This section has provided valuable tips on optimizing glass performance in skyscrapers. The following section will delve into the future of glass innovation, exploring emerging technologies and trends shaping the industry.

Conclusion

As the world continues to build upwards, the demand for innovative and high-performance glass for skyscrapers will only increase. Architectural glass manufacturers, in collaboration with architects, engineers, and contractors, are constantly pushing the boundaries of glass design and technology to meet the evolving needs of these iconic structures.

The future of glass for skyscrapers holds exciting possibilities. Emerging technologies, such as smart glass and self-cleaning coatings, will enhance energy efficiency, occupant comfort, and aesthetic appeal. Sustainable practices will remain at the forefront, with a focus on reducing environmental impact and promoting circularity. As glass manufacturers continue to innovate, we can expect even more groundbreaking advancements in the years to come.