The term “cast in skyscraper” refers to the process of forming or shaping metal or other materials into components used in the construction of skyscrapers. These components can include structural elements such as beams and columns, as well as decorative elements such as facades and ornaments.

Casting is an essential process in skyscraper construction as it allows for the creation of complex and precise shapes that would be difficult or impossible to produce using other methods. Cast components are also strong and durable, making them well-suited for the demanding requirements of high-rise buildings.

The history of casting in skyscraper construction can be traced back to the late 19th century, when cast iron was used to create the structural framework of early skyscrapers. In the early 20th century, steel became the preferred material for casting skyscraper components, and it remains the most widely used material today.

1. Structural Components

Structural components are the backbone of a skyscraper, providing the strength and support needed to withstand various forces and ensure the building’s stability. Casting plays a crucial role in shaping these components, allowing for the creation of complex and precise forms that meet the demanding requirements of high-rise structures.

- Beams

Cast steel beams are essential for supporting the weight of the skyscraper and transferring loads across its structure. They are designed to resist bending and deformation, ensuring the building’s structural integrity.

- Columns

Cast steel or concrete columns provide vertical support to the skyscraper, carrying the weight of the building and transferring it to the foundation. They are designed to withstand compression and buckling forces.

- Floor Slabs

Precast concrete floor slabs are used to create the floors of a skyscraper. They are cast in molds and then lifted into place, providing a strong and stable base for the building’s occupants.

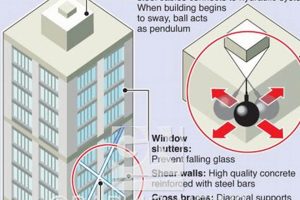

- Shear Walls

Cast-in-place concrete shear walls are used to resist lateral forces, such as wind and earthquakes. They are designed to transfer these forces to the foundation, preventing the building from swaying or collapsing.

The casting process allows for the precise shaping of these structural components, ensuring they meet the specific requirements of each skyscraper’s design. Cast components are also highly durable and can withstand the demanding conditions associated with high-rise buildings, including high winds, seismic activity, and fire.

2. Decorative Elements

Decorative elements play a significant role in the overall aesthetic appeal and architectural expression of skyscrapers. Casting techniques are widely used to create these elements, allowing for intricate designs and the incorporation of various materials.

One of the key advantages of casting for decorative elements is the ability to produce complex and detailed shapes. This is particularly important for creating ornamental features such as cornices, moldings, and sculptures. Cast elements can also be customized to reflect the unique design vision of the architect, giving each skyscraper its own distinctive character.

In addition to their aesthetic value, decorative elements can also serve practical purposes. For example, cast metal panels can be used to clad the exterior of a skyscraper, providing a protective layer against the elements while also enhancing the building’s visual appeal. Cast concrete elements can be used to create balconies and terraces, offering occupants outdoor spaces with stunning views.

The use of cast decorative elements in skyscrapers has a long history. Early skyscrapers, such as the Flatiron Building in New York City, featured elaborate cast iron facades that showcased the architectural styles of the time. In recent years, cast decorative elements have experienced a resurgence in popularity, as architects and designers seek to create visually striking and memorable high-rise buildings.

Overall, the connection between decorative elements and cast in skyscraper is essential for understanding the architectural beauty and functionality of these towering structures. Casting techniques allow architects and designers to create intricate and visually appealing elements that contribute to the overall aesthetic and practical appeal of skyscrapers.

3. Strength and Durability

In the context of skyscrapers, strength and durability are paramount considerations, and casting plays a vital role in achieving these qualities.

- Structural Integrity

Cast components form the backbone of a skyscraper’s structure, providing exceptional strength and rigidity. They are designed to withstand immense loads, including the weight of the building, occupants, and environmental forces such as wind and seismic activity.

- Fire Resistance

Cast concrete and steel elements offer superior fire resistance, protecting the building’s structural integrity and occupants during a fire. They can withstand high temperatures for extended periods, preventing collapse and ensuring safe evacuation.

- Corrosion Resistance

Cast metal components are often treated with anti-corrosion coatings or made from corrosion-resistant materials like stainless steel. This protects them from environmental factors such as moisture, salt, and chemicals, ensuring long-term durability.

- Seismic Resistance

In earthquake-prone areas, cast components are designed to absorb and dissipate seismic energy. They help maintain the building’s stability during earthquakes, reducing the risk of structural damage and collapse.

The strength and durability of cast components are essential for ensuring the safety and longevity of skyscrapers. These qualities enable skyscrapers to withstand various challenges and provide a safe and habitable environment for occupants.

4. Precision and Complexity

In the realm of skyscrapers, precision and complexity are inextricably linked to cast components, shaping their functionality and aesthetic appeal.

- Structural Precision

Cast components, such as steel be

ams and concrete columns, require precise dimensions and tolerances to ensure structural integrity. Each component must fit seamlessly into the overall framework, bearing immense weight and resisting lateral forces. - Geometric Intricacy

Casting allows for the creation of complex geometric shapes that would be difficult or impossible to achieve through other construction methods. These intricate designs contribute to the architectural expression of skyscrapers, creating visually striking facades and unique interior spaces.

- Ornamental Details

Cast elements are often used to embellish skyscrapers with intricate ornamental details, such as cornices, moldings, and sculptures. These details enhance the aesthetic appeal of the building, reflecting the architectural style and vision of the designer.

- Customized Solutions

Casting provides the flexibility to create customized components that meet the specific requirements of each skyscraper. This allows architects and engineers to design buildings that are tailored to their unique functional and aesthetic needs.

The precision and complexity inherent in cast components are fundamental to the construction of skyscrapers. They enable the realization of towering structures that combine strength, functionality, and architectural beauty, pushing the boundaries of engineering and design.

5. Historical Significance

The connection between “Historical Significance” and “cast in skyscraper” is deeply rooted in the evolution of architecture and engineering. Cast components have played a pivotal role in shaping the skylines of cities, leaving a lasting impact on the architectural landscape.

In the late 19th century, the advent of cast iron and steel enabled the construction of the first skyscrapers. These early high-rise buildings, such as the Home Insurance Building in Chicago and the Flatiron Building in New York City, featured elaborate cast iron facades that showcased the architectural styles of the time. Cast iron components allowed for intricate ornamentation and decorative details, contributing to the visual grandeur of these pioneering skyscrapers.

As skyscrapers continued to soar higher, cast steel became the preferred material for structural components. Cast steel beams and columns provided the strength and rigidity necessary to support the immense weight of these towering structures. The Empire State Building, completed in 1931, is a testament to the engineering prowess and architectural significance of cast steel in skyscraper construction.

Today, cast components continue to be an essential element in the construction of skyscrapers. While modern skyscrapers may incorporate a wider range of materials and construction techniques, cast elements remain indispensable for their strength, durability, and aesthetic appeal. They are used to create structural frameworks, decorative facades, and other architectural features that contribute to the unique identity and historical significance of each skyscraper.

Understanding the historical significance of cast in skyscraper provides valuable insights into the evolution of architecture and engineering. It highlights the ingenuity and craftsmanship of past architects and engineers, and serves as a reminder of the enduring legacy of cast components in shaping the urban skylines of today.

6. Cast Iron

Cast iron, an alloy of iron, carbon, and silicon, played a pivotal role in the early stages of skyscraper construction. Its unique properties and versatility made it an ideal material for shaping the structural and decorative elements of these towering structures.

- Structural Components

Cast iron’s exceptional strength and rigidity made it a suitable choice for constructing the load-bearing frameworks of early skyscrapers. Its ability to be cast into intricate shapes allowed for the creation of ornate facades, balconies, and other architectural details that became synonymous with the skyscraper aesthetic.

- Ornamental Details

The decorative possibilities of cast iron were fully exploited in the design of skyscraper facades. Elaborate cornices, moldings, and sculptures were cast in iron, adding visual interest and grandeur to these otherwise utilitarian structures. Cast iron’s resistance to corrosion and fire further enhanced its suitability for exterior applications.

- Fire Resistance

Cast iron’s exceptional fire resistance was a crucial consideration in skyscraper construction, where the risk of fire was significant. Its ability to withstand high temperatures without losing its structural integrity made it an invaluable material for fireproofing structural components and creating fire-resistant barriers.

- Historical Significance

Cast iron played a significant role in the development of skyscraper architecture, particularly in the late 19th and early 20th centuries. The iconic Flatiron Building in New York City, completed in 1902, is a prime example of the extensive use of cast iron in skyscraper construction. Its intricate facade and structural components showcase the versatility and aesthetic appeal of cast iron.

While steel eventually replaced cast iron as the primary material for skyscraper construction due to its superior strength-to-weight ratio, cast iron remains an important material in the construction industry. Its historical significance, durability, and aesthetic appeal continue to make it a valuable choice for certain architectural applications, particularly in the restoration and preservation of historic buildings.

7. Steel

Steel, an alloy of iron and carbon, has played a pivotal role in the construction of skyscrapers, revolutionizing the possibilities of height and architectural expression.

- Structural Framework

Steel’s exceptional strength-to-weight ratio makes it an ideal material for constructing the structural framework of skyscrapers. Its high tensile strength allows it to withstand immense loads, enabling the creation of soaring towers that can resist lateral forces like wind and seismic activity.

- Facade Elements

Steel’s versatility extends to the creation of facade elements, including curtain walls and window frames. Its ability to be formed into complex shapes and its resistance to corrosion and weathering make it a durable and aesthetically pleasing choice for exterior applications.

- Ornamental Details

Steel can be cast into intricate ornamental details, adding decorative flourishes to skyscraper facades. Its malleability allows for the creation of elaborate sculptures, cornices, and other embellishments that enhance the visual appeal of these towering structures.

- Fire Resistance

Steel’s fire resistance is a crucial consideration in skyscraper construction. Its high melting point and ability to retain its strength at elevated temperatures make it an effective material for fireproofing structural components and creating fire-resistant barriers.

The connection between steel and cast in skyscraper is evident in the iconic structures that have shaped skylines around the world. The Empire State Building, completed in 1931, stands as a testament to the strength and durability of steel, while the more recent Burj Khalifa showcases the limitless possibilities of steel construction.

8. Modern Applications

In contemporary skyscraper construction, casting techniques continue to play a vital role, albeit with modern advancements and innovative applications:

Structural Optimization

Advanced casting methods allow for the creation of complex structural components with optimized shapes and weight distribution. This results in more efficient use of materials, reduced structural loads, and improved overall building performance.

Sustainability

Sustainable casting practices, such as the use of recycled materials and energy-efficient processes, contribute to the environmental friendliness of modern skyscrapers. These techniques minimize waste, reduce carbon emissions, and promote a greener building industry.

Aesthetic Versatility

Modern casting techniques offer architects and designers greater freedom in shaping the aesthetic elements of skyscrapers. From intricate facades to sculptural details, casting enables the realization of unique and visually striking designs that enhance the urban landscape.

Cost-Effectiveness

Advanced casting technologies, such as automated casting lines and robotic finishing, have improved production efficiency and reduced labor costs. This contributes to the overall cost-effectiveness of skyscraper construction, making it more accessible and feasible in various economic contexts.

Understanding the connection between modern applications and cast in skyscraper is crucial for appreciating the ongoing evolution and advancements in high-rise construction. These innovations push the boundaries of architectural design, enhance the sustainability and efficiency of skyscrapers, and contribute to the creation of iconic structures that shape the skylines of the 21st century.

FAQs on “Cast in Skyscraper”

This section addresses frequently asked questions related to the use of casting techniques in skyscraper construction, providing clear and informative answers to common concerns and misconceptions.

Question 1: What are the advantages of using cast components in skyscrapers?

Cast components offer several advantages in skyscraper construction, including exceptional strength and durability, precise shaping for complex designs, and the ability to create intricate ornamental details. They provide structural integrity, fire resistance, and corrosion resistance, ensuring the safety and longevity of high-rise buildings.

Question 2: What materials are commonly used for casting in skyscrapers?

Historically, cast iron and steel have been the primary materials used for casting in skyscrapers. Cast iron was prevalent in early skyscrapers, offering strength and ornamental possibilities. Steel, with its superior strength-to-weight ratio, became the preferred choice for structural components, facades, and ornamental details in modern skyscrapers.

Question 3: How does casting contribute to the structural stability of skyscrapers?

Cast components form the backbone of a skyscraper’s structural framework, providing strength and rigidity. Cast steel beams and columns support immense loads, transferring weight and resisting lateral forces. Cast concrete floor slabs create stable floors, while shear walls enhance resistance to earthquakes and high winds.

Question 4: What is the role of casting in creating visually appealing skyscrapers?

Casting techniques allow for the creation of intricate and visually striking facades. Cast metal panels, cornices, moldings, and sculptures add ornamental details and architectural expression to skyscrapers. These elements contribute to the overall aesthetic appeal and unique identity of each building.

Question 5: How does casting contribute to the sustainability of skyscrapers?

Modern casting practices emphasize sustainability. Recycled materials and energy-efficient processes reduce environmental impact. Cast components can be designed for durability and longevity, minimizing the need for frequent replacements and reducing waste.

Question 6: What are the limitations of using casting in skyscraper construction?

Casting techniques may have certain limitations, such as the size and complexity of components that can be produced. Cost and production time can also be factors to consider. However, advancements in casting technologies are continuously pushing these boundaries, expanding the possibilities for innovation in skyscraper design and construction.

These FAQs provide a comprehensive overview of the use of casting in skyscraper construction, highlighting its advantages, materials, structural significance, aesthetic contributions, sustainability aspects, and limitations. Understanding these factors deepens our appreciation for the engineering and architectural marvels that skyscrapers represent.

Transition to the next article section:

The journey of skyscrapers continues to evolve, with advancements in materials, construction methods, and architectural designs constantly shaping the skylines of cities worldwide. As we explore the future of skyscrapers, the connection between casting techniques and architectural innovation remains a vital aspect of pushing the boundaries of human ingenuity and shaping the urban landscapes of tomorrow.

Tips for Optimizing Cast Components in Skyscraper Construction

To harness the full potential of casting techniques in skyscraper construction, consider these practical tips:

Tip 1: Prioritize Structural Integrity

Ensure that cast components meet the rigorous structural demands of skyscrapers. Utilize high-strength materials, precise casting processes, and thorough testing to guarantee the load-bearing capacity and stability of the structure.Tip 2: Embrace Design Innovation

Explore the creative possibilities of casting to achieve unique architectural expressions. Collaborate with architects and designers to develop intricate facades, decorative elements, and customized solutions that set your skyscraper apart.Tip 3: Enhance Sustainability

Incorporate sustainable practices into the casting process. Use recycled materials, implement energy-efficient techniques, and design cast components for durability and longevity to minimize environmental impact.Tip 4: Ensure Quality Control

Establish rigorous quality control measures throughout the casting process. Inspect raw materials, monitor production parameters, and conduct thorough testing to ensure the highest quality and consistency of cast components.Tip 5: Consider Cost-Effectiveness

Optimize casting techniques to achieve cost-effectiveness without compromising quality. Explore innovative casting methods, negotiate favorable material prices, and streamline production processes to maintain project viability.Tip 6: Foster Collaboration

Promote effective collaboration among architects, engineers, contractors, and material suppliers. Open communication and shared expertise will lead to optimized designs, efficient construction, and successful project outcomes.Tip 7: Stay Updated with Advancements

Keep abreast of the latest advancements in casting technologies and materials. Attend industry events, read technical literature, and engage with experts to stay informed about innovative solutions and best practices.Tip 8: Seek Professional Guidance

Consult with experienced professionals, such as structural engineers and casting specialists, to gain valuable insights and ensure the successful implementation of cast components in your skyscraper project.

By following these tips, you can optimize the use of casting techniques to create structurally sound, aesthetically pleasing, sustainable, and cost-effective skyscrapers that will stand the test of time.

Transition to the article’s conclusion:

As the construction industry continues to strive for innovation and sustainability, casting techniques will undoubtedly play a pivotal role in shaping the future of skyscrapers. Embracing these tips will empower architects, engineers, and contractors to harness the full potential of casting and push the boundaries of high-rise construction.

Conclusion

The exploration of “cast in skyscraper” has unveiled the profound impact of casting techniques on the design, construction, and aesthetics of these towering structures. From the structural framework to intricate ornamental details, casting plays a vital role in ensuring the strength, durability, and visual appeal of skyscrapers.

As we look ahead, the future of cast in skyscraper holds exciting possibilities. Advancements in materials, such as ultra-high-strength concrete and lightweight alloys, will enable the creation of even more resilient and sustainable skyscrapers. Innovative casting methods, such as 3D printing and robotic fabrication, will further enhance precision, efficiency, and design freedom. The integration of casting with other cutting-edge technologies, such as smart sensors and self-healing materials, will lead to the development of intelligent and adaptable skyscrapers that can respond to changing environmental and structural conditions.

By embracing the potential of cast in skyscraper, architects, engineers, and contractors can push the boundaries of high-rise construction and create iconic structures that will continue to shape the skylines of tomorrow. These skyscrapers will not only be marvels of engineering but also testaments to the ingenuity and creativity of the human spirit.