A skyscraper cast is a building element that is used to create the exterior walls of a skyscraper. It is typically made of concrete or steel and is cast in a mold to create the desired shape. Skyscraper casts are used to create a variety of different architectural features, including windows, doors, and columns.

Skyscraper casts are important because they allow architects to create buildings that are both strong and aesthetically pleasing. They are also relatively easy to install, which makes them a cost-effective option for building tall buildings. Skyscraper casts have been used in the construction of some of the world’s most iconic buildings, including the Empire State Building and the Burj Khalifa.

In addition to their structural and aesthetic benefits, skyscraper casts also have a number of historical significance. They were first developed in the late 19th century, and they played a major role in the development of modern architecture. Skyscraper casts are a testament to the ingenuity and creativity of architects and engineers, and they continue to be used in the construction of some of the world’s most impressive buildings.

1. Structural Support

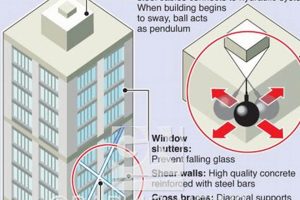

Skyscraper casts play a crucial role in providing structural support and ensuring the stability of high-rise buildings. These casts are typically made of concrete or steel, materials known for their strength and durability. By utilizing skyscraper casts, architects and engineers can create buildings that can withstand various forces, including wind, seismic activity, and the weight of the structure itself.

The structural integrity of a high-rise building is paramount, as it directly impacts the safety and well-being of its occupants. Skyscraper casts contribute to this integrity by forming a robust framework that distributes weight evenly throughout the building. This framework helps to prevent excessive stress on any one particular area, reducing the risk of structural failure.

One notable example of the importance of skyscraper casts in structural support is the Burj Khalifa, the tallest building in the world. The Burj Khalifa’s exterior is composed of reinforced concrete skyscraper casts, which provide exceptional strength and stability. These casts have enabled the building to withstand high winds and seismic activity, ensuring the safety of its occupants.

In conclusion, skyscraper casts are essential components of high-rise buildings, providing the structural support necessary to ensure their stability and safety. By understanding the connection between skyscraper casts and structural support, architects and engineers can design and construct buildings that are both aesthetically pleasing and structurally sound, creating safe and habitable spaces for communities worldwide.

2. Exterior Facade

Skyscraper casts play a pivotal role in shaping the external appearance and aesthetics of high-rise buildings. These casts serve as the building’s exterior facade, defining its overall form and visual appeal. Architects and designers utilize skyscraper casts to create unique and iconic structures that stand out in skylines worldwide.

The connection between skyscraper casts and exterior facades is evident in the variety of architectural styles and designs they enable. From the Art Deco skyscrapers of New York City to the contemporary glass and steel towers of Dubai, skyscraper casts have been instrumental in creating buildings that are both functional and aesthetically captivating.

One notable example of the importance of skyscraper casts in shaping a building’s exterior facade is the Chrysler Building in New York City. Completed in 1930, the Chrysler Building is renowned for its Art Deco design, which is largely defined by its intricate skyscraper casts. These casts feature decorative elements such as eagles, gargoyles, and geometric patterns, giving the building a distinctive and recognizable appearance.

In conclusion, skyscraper casts are essential components of high-rise buildings, providing both structural support and aesthetic appeal. By understanding the connection between skyscraper casts and exterior facades, architects and designers can create buildings that are both visually stunning and structurally sound.

3. Material Composition

The material composition of skyscraper casts plays a crucial role in determining their durability and longevity. Concrete and steel, the two primary materials used in skyscraper casts, offer unique advantages that make them ideal for this application.

Concrete is a composite material composed of cement, aggregate (such as sand or gravel), and water. When these components are mixed, they form a paste that hardens over time, creating a strong and durable material. Concrete is resistant to fire, water, and corrosion, making it an excellent choice for high-rise buildings that are exposed to various environmental conditions.

Steel, on the other hand, is an alloy primarily composed of iron and carbon. It is known for its exceptional strength and rigidity. Steel is also relatively lightweight, making it suitable for use in high-rise buildings where weight is a concern. Additionally, steel is resistant to fire and corrosion, ensuring the longevity of the structure.

The combination of strength, durability, and longevity makes concrete and steel the ideal materials for skyscraper casts. These materials can withstand the various forces and environmental conditions that high-rise buildings are subjected to, ensuring the safety and integrity of the structure for years to come.

4. Molding Process

The molding process is a fundamental aspect of skyscraper cast production, enabling the creation of precise shapes and dimensions crucial for the structural integrity and aesthetic appeal of high-rise buildings. Skyscraper casts are typically cast in molds made of materials such as rubber or fiberglass, which are designed to create the desired shape and dimensions of the final product.

The molding process begins with the creation of a master pattern, which serves as the template for the mold. The master pattern is typically made of wood or metal and is carefully crafted to match the desired shape and dimensions of the skyscraper cast. Once the master pattern is complete, it is used to create a mold, which is a negative impression of the master pattern.

The molding process involves pouring a liquid material, such as concrete or steel, into the mold and allowing it to set and harde

n. Once the material has hardened, the mold is removed, revealing the final skyscraper cast. This process ensures that each skyscraper cast is produced with the same precise shape and dimensions, ensuring consistency and quality throughout the construction process.

The precision achieved through the molding process is essential for the structural integrity of high-rise buildings. Each skyscraper cast must fit together seamlessly to create a strong and stable structure. Precise dimensions also ensure that the exterior facade of the building is visually appealing and consistent, contributing to the overall aesthetic of the skyscraper.

In conclusion, the molding process is a critical component of skyscraper cast production, enabling the creation of precise shapes and dimensions. This precision is essential for both the structural integrity and aesthetic appeal of high-rise buildings, ensuring that they meet the highest standards of quality and safety.

5. Architectural Versatility

Skyscraper casts are renowned for their architectural versatility, as they can be used to create a wide range of features that enhance the functionality and aesthetic appeal of high-rise buildings.

- Windows

Skyscraper casts are commonly used to create windows, providing natural light and ventilation while maintaining the structural integrity of the building. They can be designed in various shapes and sizes, contributing to the overall aesthetic of the facade. - Doors

Skyscraper casts can also be used to create doors, providing access to the building’s interior. They can be designed to complement the architectural style of the building and can incorporate security features to ensure the safety of occupants. - Columns

Skyscraper casts are utilized to create columns, which are vertical structural elements that support the weight of the building. They can be designed with intricate details and patterns, adding a decorative touch to the interior or exterior of the building. - Other Features

Beyond windows, doors, and columns, skyscraper casts can also be used to create other architectural features such as balconies, cornices, and spandrels. These elements contribute to the overall visual appeal of the building and can enhance its functionality.

In conclusion, the architectural versatility of skyscraper casts allows architects and engineers to create high-rise buildings that are both aesthetically pleasing and structurally sound. By incorporating windows, doors, columns, and other features into their designs, skyscraper casts contribute to the functionality, safety, and overall appeal of these iconic structures.

6. Cost-Effectiveness

Skyscraper casts offer cost-effective solutions for constructing tall buildings, making them a practical and efficient choice for modern architecture. The use of pre-cast concrete or steel components reduces construction time and labor costs compared to traditional on-site construction methods. This prefabrication process allows for better quality control and precision, minimizing errors and the need for rework, ultimately leading to cost savings.

The durability and longevity of skyscraper casts contribute to cost-effectiveness in the long run. These casts are designed to withstand various environmental conditions, reducing the need for frequent maintenance or repairs. Additionally, the energy efficiency of modern skyscraper casts, achieved through advanced insulation techniques, can result in lower energy consumption and operational costs for building owners.

In conclusion, the cost-effectiveness of skyscraper casts stems from their efficient production process, durable nature, and energy efficiency. By leveraging these advantages, architects and engineers can design and construct tall buildings that are both economical and sustainable, meeting the demands of modern urban development.

7. Historical Significance

Skyscraper casts played a pivotal role in the development of modern architecture, revolutionizing the way tall buildings were designed and constructed. Their introduction in the late 19th century marked a shift towards prefabrication and modular construction, enabling the efficient and cost-effective creation of high-rise structures.

The use of skyscraper casts allowed architects to explore new design possibilities and push the boundaries of architectural expression. Notable examples include the Empire State Building and the Chrysler Building in New York City, both of which utilized skyscraper casts extensively in their construction. These buildings showcased the potential of skyscraper casts to create visually striking and structurally sound facades, contributing to the iconic skylines of cities worldwide.

The historical significance of skyscraper casts extends beyond their aesthetic impact. Their prefabricated nature facilitated rapid construction, making them a practical solution for the growing demand for tall buildings in urban areas. Moreover, the durability and fire resistance of skyscraper casts ensured the longevity and safety of these structures, making them a valuable asset to modern architecture.

In conclusion, the historical significance of skyscraper casts lies in their role as a catalyst for the development of modern architecture. Their prefabrication, aesthetic versatility, and structural integrity enabled the creation of iconic high-rise buildings that continue to shape skylines and influence architectural design to this day.

8. Iconic Structures

Skyscraper casts have played a crucial role in the construction of some of the world’s most iconic skyscrapers, including the Empire State Building and the Burj Khalifa. These casts have enabled architects and engineers to create buildings that are both visually striking and structurally sound, shaping the skylines of cities worldwide.

- Structural Support: Skyscraper casts provide the structural support necessary to construct tall buildings, ensuring their stability and safety. The Empire State Building, for example, utilizes skyscraper casts to distribute the weight of the structure evenly, preventing excessive stress on any one particular area.

- Aesthetic Appeal: Skyscraper casts contribute significantly to the aesthetic appeal of high-rise buildings. The Chrysler Building is renowned for its Art Deco facade, which is largely defined by its intricate skyscraper casts. These casts feature decorative elements such as eagles, gargoyles, and geometric patterns, giving the building a distinctive and recognizable appearance.

- Durability and Longevity: Skyscraper casts are made of durable materials such as concrete and steel, ensuring the longevity of the structures they support. The Burj Khalifa, the tallest building in the world, is composed of reinforced concrete skyscraper casts, which

provide exceptional strength and stability, allowing the building to withstand high winds and seismic activity. - Versatility and Innovation: Skyscraper casts offer architects and engineers a high degree of versatility and innovation in their designs. They can be used to create a wide range of architectural features, including windows, doors, columns, and balconies. This versatility allows for the creation of unique and iconic structures that push the boundaries of architectural expression.

In conclusion, skyscraper casts have played a pivotal role in the construction of iconic skyscrapers like the Empire State Building and the Burj Khalifa. Their structural support, aesthetic appeal, durability, and versatility have enabled architects and engineers to create buildings that are both visually stunning and structurally sound, shaping the skylines of cities worldwide.

FAQs about Skyscraper Casts

This section provides answers to frequently asked questions about skyscraper casts, offering valuable insights into their composition, applications, and significance in modern architecture.

Question 1: What are skyscraper casts made of?

Skyscraper casts are typically made of concrete or steel, two materials renowned for their strength, durability, and ability to withstand various environmental conditions. Concrete casts are composed of cement, aggregate, and water, while steel casts are primarily composed of iron and carbon.

Question 2: What is the purpose of skyscraper casts?

Skyscraper casts serve multiple purposes in high-rise buildings. They provide structural support, forming a robust framework that distributes weight evenly throughout the building. Additionally, they contribute to the exterior facade, shaping the building’s external appearance and aesthetics.

Question 3: How are skyscraper casts manufactured?

Skyscraper casts are produced through a molding process. A master pattern is first created, and a mold is made from this pattern. Liquid concrete or steel is then poured into the mold and allowed to harden, resulting in the final cast.

Question 4: What are the advantages of using skyscraper casts?

Skyscraper casts offer several advantages, including structural stability, enhanced aesthetics, cost-effectiveness, and historical significance. They enable the creation of tall buildings that are both strong and visually appealing.

Question 5: Where are skyscraper casts commonly used?

Skyscraper casts are widely used in the construction of high-rise buildings, particularly in urban areas. Notable examples include the Empire State Building and the Burj Khalifa, showcasing the versatility and significance of skyscraper casts in modern architecture.

Question 6: What is the future of skyscraper casts?

Skyscraper casts continue to play a vital role in modern architecture, and their future applications are promising. Advancements in materials and construction techniques may lead to even more innovative and sustainable uses of skyscraper casts in the years to come.

In conclusion, skyscraper casts are essential components of high-rise buildings, providing structural support, aesthetic appeal, and historical significance. Their continued use and evolution will contribute to the construction of even more iconic and sustainable structures in the future.

Transition to the next article section:

The diverse applications and benefits of skyscraper casts highlight their importance in modern architecture. As we explore the nuances of skyscraper design, we will delve into the innovative techniques and materials that are shaping the future of high-rise construction.

Tips for Utilizing Skyscraper Casts Effectively

Skyscraper casts offer a unique combination of structural support, aesthetic appeal, and cost-effectiveness. To maximize their benefits, consider the following tips:

Tip 1: Prioritize Structural Integrity

Skyscraper casts play a crucial role in maintaining the structural stability of high-rise buildings. Ensure they are designed and constructed using high-strength materials and precise engineering to withstand various forces, including wind, seismic activity, and the weight of the structure.

Tip 2: Explore Creative Facade Options

Skyscraper casts offer architects the freedom to explore diverse facade designs. Utilize their versatility to create unique and visually striking exteriors that enhance the building’s aesthetics and contribute to the overall urban landscape.

Tip 3: Optimize Production and Installation

To maximize cost-effectiveness, streamline the production and installation processes of skyscraper casts. Collaborate with experienced manufacturers and contractors to minimize lead times, reduce labor costs, and ensure efficient on-site assembly.

Tip 4: Consider Sustainability and Durability

Choose materials and finishes for skyscraper casts that promote sustainability and longevity. Opt for eco-friendly concrete mixes and durable coatings to minimize environmental impact and ensure the building’s longevity.

Tip 5: Seek Expert Advice and Collaboration

Engage with architects, engineers, and contractors who possess specialized knowledge in skyscraper cast design and installation. Their expertise will ensure that the casts meet the highest standards of safety, performance, and aesthetics.

By incorporating these tips into your skyscraper design and construction strategy, you can harness the full potential of skyscraper casts. These versatile elements will not only enhance the structural integrity and visual appeal of your building but also contribute to its overall sustainability and cost-effectiveness.

Conclusion

Skyscraper casts have emerged as indispensable elements in modern architecture, transforming the way tall buildings are designed and constructed. Their ability to provide structural support, enhance aesthetics, and optimize cost-effectiveness has made them a preferred choice for architects and engineers worldwide.

As we look towards the future of high-rise architecture, skyscraper casts will undoubtedly continue to play a pivotal role. Advancements in materials and construction techniques will lead to even more innovative and sustainable applications of these versatile elements. Architects and engineers will push the boundaries of design, utilizing skyscraper casts to create buildings that are not only structurally sound and visually stunning but also environmentally conscious and energy-efficient.

The legacy of skyscraper casts is one of innovation, functionality, and aesthetic appeal. As we continue to build upwards, these remarkable components will undoubtedly shape the skylines of tomorrow, inspiring future generations of architects and engineers to reach for even greater heights.