In the construction of skyscrapers, metal supports play a vital role in ensuring structural integrity and stability. These supports, typically composed of steel or reinforced concrete, form the backbone of a skyscraper, providing the necessary strength and rigidity to withstand various forces, including gravity, wind, and seismic activity.

The use of metal supports in skyscrapers offers several advantages. Firstly, metal possesses exceptional strength-to-weight ratio, allowing for the construction of tall and slender structures without compromising safety. Secondly, metal supports are highly resistant to corrosion and fire, ensuring durability and longevity. Additionally, metal is relatively easy to fabricate and assemble, making it a practical and cost-effective construction material.

The history of metal supports in skyscrapers can be traced back to the late 19th century, with the advent of the steel-framed skyscraper. The Home Insurance Building in Chicago, constructed in 1885, is widely regarded as the first skyscraper to incorporate a metal frame. Since then, metal supports have become an indispensable element in the design and construction of skyscrapers, enabling the realization of iconic structures that reshape skylines around the world.

1. Strength-to-weight ratio

In the context of metal supports in skyscrapers, strength-to-weight ratio is a crucial factor that enables the construction of tall and slender structures without compromising safety. Strength-to-weight ratio refers to the amount of force a material can withstand relative to its weight. Metal, particularly steel, possesses an exceptional strength-to-weight ratio, making it an ideal material for skyscraper construction.

The high strength-to-weight ratio of metal supports allows skyscrapers to withstand various forces, including gravity, wind, and seismic activity. Steel, for instance, has a strength-to-weight ratio that is several times higher than concrete, making it a more efficient choice for tall buildings. By using metal supports with a high strength-to-weight ratio, architects and engineers can create skyscrapers that are both strong and lightweight, reducing the overall structural weight and minimizing the need for additional support systems.

In real-world applications, the strength-to-weight ratio of metal supports has played a significant role in the construction of some of the world’s tallest and most iconic skyscrapers. The Burj Khalifa, the tallest building in the world, utilizes a steel-reinforced concrete core and metal supports to achieve its remarkable height and structural stability. Similarly, the Shanghai Tower, another supertall skyscraper, employs a combination of steel and concrete supports to resist the strong winds and seismic forces common in the region.

Understanding the connection between strength-to-weight ratio and metal supports in skyscrapers is essential for architects, engineers, and construction professionals involved in the design and construction of tall buildings. By leveraging the high strength-to-weight ratio of metal supports, they can create structures that are both safe and efficient, pushing the boundaries of architectural design and engineering innovation.

2. Corrosion resistance

In the context of metal supports in skyscrapers, corrosion resistance is a crucial property that ensures the longevity and structural integrity of these towering structures. Corrosion is the deterioration of metal due to chemical reactions with its surrounding environment, leading to the formation of rust and weakening of the metal’s structural properties.

Metal supports in skyscrapers are constantly exposed to various corrosive agents, including moisture, oxygen, and pollutants in the air. Without adequate corrosion resistance, metal supports can deteriorate over time, compromising the stability and safety of the building. Therefore, selecting corrosion-resistant metals and applying protective coatings are essential measures to safeguard the integrity of metal supports.

Stainless steel is a commonly used material for metal supports in skyscrapers due to its exceptional corrosion resistance. Stainless steel contains alloying elements such as chromium, which forms a protective oxide layer on the metal’s surface, preventing further corrosion. Other corrosion-resistant metals include aluminum alloys and weathering steel, which develop a protective patina over time, enhancing their resistance to corrosion.

In addition to material selection, protective coatings play a vital role in enhancing the corrosion resistance of metal supports. Galvanization, a process of applying a zinc coating to steel, is widely used to protect metal supports from corrosion. Zinc acts as a sacrificial anode, corroding in place of the steel and preventing the underlying metal from rusting.

Understanding the importance of corrosion resistance and implementing effective corrosion control measures are critical for ensuring the durability and safety of metal supports in skyscrapers. By utilizing corrosion-resistant materials and applying appropriate protective coatings, architects, engineers, and building owners can safeguard the integrity of these structures for decades to come.

3. Fire resistance

In the context of skyscrapers, fire resistance is a critical property of metal supports, as fires pose a significant threat to the structural integrity and safety of these towering structures. Metal supports play a crucial role in maintaining the stability of a skyscraper during a fire by resisting the effects of extreme heat and flames.

The fire resistance of metal supports is determined by several factors, including the type of metal used, its thickness, and the presence of protective coatings. Steel, a commonly used metal for skyscraper construction, has inherent fire resistance due to the formation of a protective oxide layer on its surface. However, the thickness of the steel also plays a vital role, as thicker steel sections can withstand higher temperatures for longer durations.

To enhance the fire resistance of metal supports further, protective coatings such as intumescent paint or spray-applied fireproofing materials are often applied. These coatings expand and create a protective barrier when exposed to heat, insulating the underlying metal and delaying its failure.

The practical significance of understanding the connection between fire resistance and metal supports in skyscrapers cannot be overstated. By incorporating fire-resistant metal supports into the design of skyscrapers, architects and engineers can ensure that these structures can withstand the devastating effects of fire, protecting the lives of o

ccupants and safeguarding the integrity of the building.

Real-life examples of the importance of fire-resistant metal supports can be seen in the aftermath of major fires in skyscrapers. In the 1993 World Trade Center bombing, the steel supports of the North Tower withstood the intense heat of the fire for over an hour, allowing for the evacuation of thousands of people. Similarly, in the 2007 Windsor Tower fire in Madrid, Spain, the metal supports maintained the structural integrity of the building, preventing a catastrophic collapse.

In conclusion, the connection between fire resistance and metal supports in skyscrapers is critical for ensuring the safety and structural integrity of these towering structures. By incorporating fire-resistant metal supports into the design, architects and engineers can mitigate the risks associated with fires, protecting lives and property.

4. Fabrication and assembly

Fabrication and assembly play a crucial role in the construction of metal supports for skyscrapers. The efficient and precise fabrication of metal components and their subsequent assembly on-site are essential for ensuring the structural integrity and safety of these towering structures.

- Precision engineering

The fabrication of metal supports for skyscrapers requires precision engineering to meet exact specifications and ensure proper fit during assembly. Advanced manufacturing techniques, such as computer-controlled cutting and welding, are employed to produce high-quality components with minimal tolerances.

- Modular construction

Metal supports are often constructed using modular components, which are prefabricated off-site and assembled on-site. This approach allows for efficient construction and reduces the need for extensive on-site welding, leading to improved quality control and reduced construction time.

- Bolted connections

Bolted connections are commonly used to assemble metal supports in skyscrapers. High-strength bolts are used to connect individual components, ensuring a secure and reliable connection. Bolted connections allow for easy disassembly if necessary, facilitating maintenance and repairs.

- Field welding

In some cases, field welding is necessary to connect metal supports on-site. This requires skilled welders and strict adherence to welding procedures to ensure the integrity of the connections. Field welding is often used for complex connections or for making adjustments during the assembly process.

The efficient fabrication and assembly of metal supports are crucial for the successful construction of skyscrapers. By leveraging precision engineering, modular construction, bolted connections, and field welding, architects and engineers can create structurally sound and visually striking metal support systems that form the backbone of these iconic structures.

5. Structural integrity

In the context of skyscrapers, structural integrity refers to the ability of the building to withstand various forces and maintain its stability. Metal supports play a vital role in ensuring the structural integrity of skyscrapers by providing strength, rigidity, and stability to the overall structure.

The connection between structural integrity and metal supports in skyscrapers is crucial because metal supports act as the backbone of these towering structures,

To ensure the structural integrity of skyscrapers, metal supports are designed to resist various types of forces and deformations. These forces include:

- Gravity: Metal supports must be strong enough to bear the weight of the entire building, including its occupants, furnishings, and equipment.

- Wind: Metal supports must be able to withstand lateral forces caused by wind, which can cause the building to sway or vibrate.

- Seismic forces: In earthquake-prone areas, metal supports must be designed to resist the dynamic forces generated by earthquakes.

To achieve the necessary structural integrity, metal supports in skyscrapers are typically made of high-strength steel or reinforced concrete. These materials have the strength and rigidity to resist the aforementioned forces and maintain the stability of the building.

Understanding the connection between structural integrity and metal supports in skyscrapers is essential for architects, engineers, and construction professionals involved in the design and construction of these tall buildings. By ensuring the structural integrity of metal supports, they can create safe and habitable spaces for people to live, work, and visit.

6. Seismic resilience

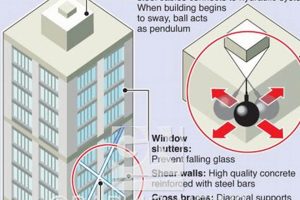

In the context of towering skyscrapers, seismic resilience refers to the ability of these structures to withstand the dynamic forces generated by earthquakes. Metal supports play a crucial role in ensuring the seismic resilience of skyscrapers by providing strength, ductility, and energy dissipation capacity to the overall structure.

- Moment-resisting frames

Moment-resisting frames are a common structural system used in skyscrapers to resist lateral forces, including those caused by earthquakes. These frames are composed of metal beams and columns that are connected using rigid joints, allowing them to resist bending and twisting forces. In the event of an earthquake, moment-resisting frames dissipate energy through plastic deformation of the metal beams, preventing brittle failure and safeguarding the integrity of the building.

- Ductile connections

Ductile connections are essential for ensuring the seismic resilience of metal supports in skyscrapers. These connections are designed to yield and deform under seismic forces without losing their load-carrying capacity. This ductility allows the building to absorb and dissipate energy, reducing the risk of catastrophic failure. Ductile connections are typically achieved through the use of high-strength bolts or welded joints.

- Energy dissipation devices

Energy dissipation devices are incorporated into metal supports in skyscrapers to enhance their seismic resilience. These devices are designed to absorb and dissipate energy from earthquake forces, reducing the amount of energy that is transferred to the rest of the building. Common energy dissipation devices include viscous dampers, friction dampers, and tuned mass dampers.

- Base isolation systems

Base isolation systems are used in some skyscrapers to reduce the transmission of earthquake forces to the building. These systems are installed at the base of the building and consist of layers of flexible materials, such as rubber or lead-rubber bearings. By isolating the building from the ground, base isolation systems significantly reduce the seismic forces that are experienced by the metal supports and the rest of the structure.

By incorporating these seismic resilience features into the metal supports of skyscrapers, architects and engineers can create structures that are better equip

ped to withstand the damaging effects of earthquakes, ensuring the safety and well-being of occupants and minimizing the risk of structural failure.

7. Design flexibility

In the realm of architecture, design flexibility refers to the ability of a structure to adapt to changing needs and aesthetic preferences without compromising its structural integrity. Metal supports play a pivotal role in achieving design flexibility in skyscrapers, offering architects and engineers a versatile and adaptable framework to realize their creative visions.

The inherent strength and formability of metal make it an ideal material for creating complex and innovative structural systems. Metal supports can be easily manipulated and shaped to conform to various architectural designs, allowing architects to explore unique and expressive forms for their skyscrapers. This design flexibility extends to the interior of the building as well, as metal supports can be configured to accommodate diverse space planning requirements, enabling efficient and adaptable floor plans.

Real-life examples abound that showcase the practical significance of design flexibility in metal supports for skyscrapers. The Burj Khalifa, the world’s tallest building, utilizes a central reinforced concrete core surrounded by a steel diagrid exoskeleton. This innovative structural system not only provides exceptional strength and stability but also allows for flexible interior layouts, enabling the building to house a diverse range of commercial, residential, and hospitality spaces.

Another notable example is the Shanghai Tower, which features a distinctive twisting form achieved through the use of metal supports. The tower’s unique shape not only enhances its aesthetic appeal but also optimizes wind resistance, reducing structural loads and improving overall efficiency.

Understanding the connection between design flexibility and metal supports in skyscrapers is crucial for architects and engineers involved in the design and construction of these towering structures. By leveraging the inherent versatility of metal, they can create skyscrapers that are not only structurally sound but also adaptable to evolving needs and design trends, ensuring their continued relevance and usability for years to come.

FAQs on Metal Supports in Skyscrapers

Metal supports play a vital role in the construction and structural integrity of skyscrapers. Here are some frequently asked questions and their answers:

Question 1: Why are metal supports important in skyscrapers?

Metal supports are essential in skyscrapers because they provide strength, stability, and rigidity to these towering structures. Metal’s high strength-to-weight ratio allows for the construction of tall and slender buildings without compromising safety. Additionally, metal supports are resistant to corrosion, fire, and seismic forces, ensuring the longevity and durability of skyscrapers.

Question 2: What types of metal are commonly used in skyscraper supports?

Steel is the most commonly used metal for skyscraper supports due to its exceptional strength and durability. Stainless steel is also used for its corrosion resistance, while aluminum alloys are employed for their lightweight properties.

Question 3: How are metal supports connected in skyscrapers?

Metal supports in skyscrapers are typically connected using high-strength bolts, rivets, or welding. Bolted connections allow for easy disassembly if necessary, while welding provides a permanent and secure connection. The choice of connection method depends on the specific design and requirements of the skyscraper.

Question 4: How do metal supports contribute to the seismic resilience of skyscrapers?

Metal supports are crucial for the seismic resilience of skyscrapers by providing strength and ductility. Ductile connections allow the metal supports to deform and absorb energy during an earthquake, reducing the risk of catastrophic failure. Additionally, energy dissipation devices can be incorporated into metal supports to further enhance seismic resilience.

Question 5: What are the advantages of using metal supports in skyscrapers compared to other materials?

Metal supports offer several advantages over other materials for skyscraper construction. Metal’s high strength-to-weight ratio enables the construction of tall and slender buildings. Metal supports are also resistant to corrosion, fire, and seismic forces, providing long-term durability and safety. Additionally, metal is relatively easy to fabricate and assemble, making it a cost-effective construction material.

Question 6: How have metal supports evolved over time in skyscraper construction?

Metal supports in skyscrapers have evolved over time with advancements in metallurgy and engineering techniques. Early skyscrapers used wrought iron supports, which were later replaced by steel supports. The use of high-strength steel and composite materials has further enhanced the strength and durability of metal supports, allowing for the construction of even taller and more complex skyscrapers.

Understanding these FAQs provides a comprehensive overview of the importance and applications of metal supports in skyscrapers. These supports are crucial for ensuring the structural integrity, safety, and longevity of these towering structures.

Transition to the next article section: Metal Supports in Skyscrapers: Design Considerations

Tips for Utilizing Metal Supports in Skyscrapers

Metal supports play a pivotal role in the structural integrity and design of skyscrapers. Here are a few tips to optimize their use:

Tip 1: Choose the Right Metal for the Job

The type of metal used for supports should align with the specific requirements of the skyscraper. Steel is a common choice for its strength and durability, while stainless steel offers corrosion resistance and aluminum alloys provide lightweight properties.

Tip 2: Ensure Proper Connections

The connections between metal supports should be strong and reliable to maintain structural stability. High-strength bolts, rivets, or welding techniques should be employed to ensure a secure connection.

Tip 3: Consider Seismic Resilience

In earthquake-prone areas, metal supports should be designed to withstand seismic forces. Ductile connections and energy dissipation devices can enhance the seismic resilience of metal supports.

Tip 4: Optimize Design for Efficiency

The design of metal supports should aim to maximize efficiency without compromising strength. Optimizing the cross-sectional shape and using lightweight materials can reduce material usage and construction costs.

Tip 5: Protect Against Corrosion

Metal supports exposed to moisture or corrosive environments should be protected against corrosion. Galvanization, stainless steel, or protective coatings can prevent rust and extend the lifespan of the supports.

Tip 6: Plan for Future Maintenance

Metal supports may require maintenance or replacement over time. Consider accessibility and ease of maintenance when designing the support system to minimize future disruptions.

By following these tips, architects, engineers, and construction professionals can leverage the benefits of metal supports to create safe, durable, and visually striking skyscrapers.

Key Takeaways

- Choose the

appropriate metal based on specific requirements. - Ensure robust and reliable connections.

- Incorporate seismic resilience measures.

- Optimize design for efficiency and cost-effectiveness.

- Protect against corrosion to enhance longevity.

- Plan for future maintenance and accessibility.

By implementing these tips, metal supports can continue to play a crucial role in shaping the skylines of the future with their strength, durability, and versatility.

Conclusion

In the realm of architectural engineering, metal supports stand as the backbone of skyscrapers, enabling the construction of these towering structures that reshape skylines and redefine urban landscapes. Throughout this exploration, we have delved into the significance of metal supports, examining their various aspects, including strength-to-weight ratio, corrosion resistance, fire resistance, fabrication and assembly, structural integrity, seismic resilience, design flexibility, and practical applications.

Metal supports provide exceptional strength and stability to skyscrapers, allowing them to withstand the immense weight of the structure and the dynamic forces of nature, such as wind and earthquakes. Their inherent durability and resistance to corrosion and fire ensure the longevity and safety of these buildings, protecting occupants and preserving the integrity of the urban environment. The versatility of metal supports enables architects and engineers to explore innovative and visually striking designs, pushing the boundaries of architectural expression. As we look to the future of skyscraper construction, metal supports will undoubtedly continue to play a pivotal role, supporting the creation of sustainable, resilient, and awe-inspiring structures that shape the skylines of tomorrow.