A 3D printed skyscraper model is a three-dimensional representation of a skyscraper created using 3D printing technology. It serves as a miniature replica of the actual building, providing architects, engineers, and construction professionals with a tangible representation of the design’s form and scale.

3D printed skyscraper models offer several advantages. They allow for the visualization of complex architectural concepts, enabling stakeholders to better understand the building’s design and functionality. They also facilitate design iterations and modifications, allowing changes to be made more easily and efficiently. Moreover, these models can be used for testing and analysis purposes, such as wind tunnel experiments and structural simulations.

3D printed skyscraper models are becoming increasingly common as 3D printing technology advances. They play a significant role in the design and construction process, providing a valuable tool for architects, engineers, and contractors alike.

1. Accuracy

Accuracy is a crucial aspect of 3D printed skyscraper models. Unlike traditional methods of model making, 3D printing allows for highly precise and detailed models to be created. This is particularly important for skyscraper models, as even small errors in scale or proportion can have significant implications for the final building.

- Precision and Detail: 3D printing technology enables the creation of models with exceptional precision and detail. This allows architects and engineers to accurately represent complex architectural features, such as intricate facades, curved surfaces, and small-scale elements.

- Dimensional Accuracy: 3D printed models are highly dimensionally accurate, ensuring that the model’s measurements precisely match the intended design. This is essential for ensuring that the model can be used for accurate analysis and planning purposes.

- Quality Control: The accuracy of 3D printed models is also enhanced by rigorous quality control processes. Models are carefully inspected and measured to ensure that they meet the required specifications, minimizing the risk of errors or defects.

- Validation and Testing: 3D printed skyscraper models can be used for validation and testing purposes, such as wind tunnel experiments and structural analysis. The high accuracy of these models ensures that the results obtained from these tests are reliable and can be used to inform design decisions.

In conclusion, the accuracy of 3D printed skyscraper models is a key advantage that sets them apart from traditional methods. This accuracy enables architects, engineers, and construction professionals to create highly precise and reliable models that can be used for a wide range of purposes, from visualization and design validation to feasibility testing and quality control.

2. Customization

Customization is a key advantage of 3D printed skyscraper models. Unlike traditional methods of model making, 3D printing allows for highly customized models to be created, enabling architects and engineers to accurately represent even the most complex architectural features.

- Facade Customization: 3D printed models can be customized to include intricate facade details, such as windows of various shapes and sizes, balconies with unique designs, and decorative elements like cornices and moldings.

- Interior Customization: 3D printed models can also be customized to include interior details, such as different room layouts, staircases, and even furniture and fixtures. This level of customization allows architects to explore different design options and make informed decisions before construction begins.

- Structural Customization: 3D printing technology enables the creation of models with customized structural elements, such as reinforced concrete columns, steel beams, and load-bearing walls. This allows engineers to test different structural configurations and optimize the building’s design for strength and stability.

- Sustainability Customization: 3D printed models can be customized to incorporate sustainable design features, such as solar panels, green roofs, and rainwater harvesting systems. This allows architects and engineers to explore different sustainability strategies and make informed decisions about the building’s environmental impact.

In conclusion, the customization capabilities of 3D printed skyscraper models provide architects and engineers with a powerful tool to explore design options, test different configurations, and make informed decisions throughout the design and construction process.

3. Cost-effective

The cost-effectiveness of 3D printing technology is a significant advantage for 3D printed skyscraper models. Traditional methods of model making, such as handcrafting or CNC machining, can be time-consuming and expensive, especially for large and complex models. 3D printing, on the other hand, offers a more cost-effective solution.

The cost savings associated with 3D printing are primarily due to automation and reduced material waste. 3D printers operate autonomously, eliminating the need for manual labor and reducing labor costs. Additionally, 3D printing uses only the material necessary to create the model, minimizing material waste and associated costs.

The cost-effectiveness of 3D printed skyscraper models has a practical impact on the design and construction process. It allows architects and engineers to create multiple models for design iterations and testing purposes without breaking the bank. This flexibility and affordability contribute to more innovative and optimized designs.

In conclusion, the cost-effectiveness of 3D printing technology is a key factor driving the adoption of 3D printed skyscraper models. It enables architects and engineers to create accurate, customized, and cost-effective models that support better decision-making and enhance the overall design and construction process.

4. Time-saving

In the context of 3D printed skyscraper models, the time-saving aspect of 3D printing technology offers substantial benefits throughout the design and construction process.

- Rapid Prototyping: 3D printing enables rapid prototyping, allowing architects and engineers to quickly create physical models of their designs. T

his significantly reduces the time required for design iterations and testing, as compared to traditional methods that rely on manual labor or outsourcing. - Design Optimization: The time-saving advantage of 3D printing facilitates design optimization. Architects and engineers can explore different design options and make changes more efficiently, enabling them to refine their designs and improve the overall quality of the building.

- Construction Planning: 3D printed skyscraper models can be used for construction planning and coordination. By providing a physical representation of the building, these models help contractors visualize the project, plan the construction sequence, and identify potential challenges, leading to improved efficiency and reduced construction time.

- Communication and Collaboration: 3D printed models serve as effective communication tools, facilitating collaboration among architects, engineers, contractors, and other stakeholders. The ability to quickly create and share physical models enhances understanding, reduces miscommunication, and streamlines the decision-making process, saving valuable time.

In conclusion, the time-saving capabilities of 3D printing technology have revolutionized the creation of 3D printed skyscraper models. This has not only accelerated the design and construction process but also improved the quality of communication and collaboration, ultimately contributing to more efficient and successful building projects.

5. Sustainability

In the context of 3D printed skyscraper models, sustainability plays a crucial role in reducing material waste and promoting environmentally conscious practices throughout the design and construction process.

- Material Efficiency: 3D printing technology enables the efficient use of materials by building models layer by layer, using only the necessary material to create the desired shape. This reduces material waste compared to traditional methods like CNC machining or handcrafting, which often involve cutting or shaping excess material.

- Recyclable Materials: Many 3D printing materials are recyclable, allowing for sustainable practices in model making. Architects and engineers can choose eco-friendly materials like PLA (polylactic acid) or PETG (polyethylene terephthalate glycol), which can be recycled after use, minimizing environmental impact.

- Reduced Carbon Footprint: By using less material and optimizing material usage, 3D printing contributes to a reduced carbon footprint in the production of skyscraper models. This aligns with the growing emphasis on sustainable practices in the construction industry.

- Design Optimization: The iterative nature of 3D printing allows architects and engineers to explore design options and optimize their models for sustainability. They can experiment with different materials and structural configurations to reduce material usage and improve the overall environmental performance of the building.

In conclusion, the sustainable advantages of 3D printed skyscraper models go beyond material efficiency and waste reduction. They encompass a broader commitment to environmentally responsible practices and contribute to the sustainable development of the construction industry.

6. Collaboration

In the context of 3D printed skyscraper models, collaboration is essential for ensuring that the design meets the needs of all stakeholders and that the final building is successful. 3D printed models serve as a shared platform for architects, engineers, contractors, and other project participants to visualize, discuss, and refine the design.

The ease with which 3D printed models can be shared facilitates effective collaboration. Digital models can be easily distributed via email or cloud-based platforms, allowing stakeholders to access and review the model from anywhere, at any time. This eliminates the need for physical meetings or the transportation of large-scale physical models, saving time and resources.

The ability to share 3D printed models also promotes real-time feedback and input from stakeholders. Architects and engineers can incorporate feedback into the design process more efficiently, leading to better decision-making and improved design outcomes. Collaboration is particularly important for skyscraper models, as these projects often involve complex designs and require input from multiple disciplines.

In conclusion, the collaborative nature of 3D printed skyscraper models is a key advantage that enables effective communication, feedback, and decision-making among stakeholders. By facilitating collaboration, 3D printed models contribute to the success and efficiency of skyscraper design and construction projects.

7. Education

In the context of “3d printed skyscraper model,” this educational aspect plays a crucial role in architectural education and professional development. 3D printed skyscraper models serve as valuable teaching tools that enhance students’ understanding of complex architectural concepts.

- Visualization and Spatial Reasoning: 3D printed skyscraper models provide students with a tangible representation of architectural designs, allowing them to visualize and comprehend the spatial relationships and proportions of a building. This is particularly beneficial for understanding complex skyscraper structures, where scale and proportions are critical.

- Structural Analysis: 3D printed skyscraper models can be used to demonstrate structural principles and load-bearing systems. By manipulating and testing the physical models, students can gain a deeper understanding of how forces are distributed and how structural elements interact within a skyscraper.

- Design Iteration and Refinement: 3D printed models allow students to iterate and refine their designs quickly and easily. They can experiment with different design options, make changes, and visualize the impact of those changes in a tangible way, fostering a hands-on approach to architectural design.

- Collaboration and Presentation: 3D printed skyscraper models facilitate collaboration among students and with instructors. They provide a common reference point for discussions, presentations, and critiques, enabling students to share and evaluate design ideas more effectively.

In conclusion, the educational value of 3D printed skyscraper models extends beyond mere representation. They are powerful tools that enhance students’ comprehension, critical thinking, and design skills, preparing them for successful careers in architecture and related fields.

8. Feasibility testing

3D printed skyscraper models play a critical role in the feasibility testing of skyscraper designs, allowing architects and engineers to evaluate the viability of their designs before construction begins. These

models can be subjected to various tests to assess their performance and identify potential issues.

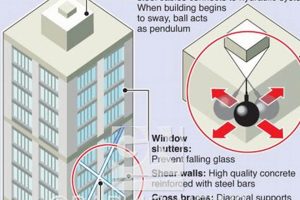

- Wind Tunnel Testing: 3D printed skyscraper models can be tested in wind tunnels to assess their aerodynamic performance and wind resistance. This is particularly important for tall buildings, which are susceptible to wind-induced vibrations and other structural challenges. Wind tunnel testing helps engineers optimize the building’s shape and structural design to minimize wind loads and ensure stability.

- Structural Analysis: 3D printed skyscraper models can be used for structural analysis to evaluate the building’s ability to withstand various loads, including gravity, wind, and seismic forces. Engineers apply different loads to the model and measure its response to determine its strength, stiffness, and stability. This testing helps ensure that the building is structurally sound and meets safety requirements.

- Material Testing: 3D printed skyscraper models can be used to test the mechanical properties of different materials and construction techniques. By printing models with different materials or using different printing techniques, engineers can assess their strength, durability, and other performance characteristics. This information is crucial for selecting the most suitable materials and construction methods for the actual building.

- Construction Simulation: 3D printed skyscraper models can be used to simulate the construction process and identify potential challenges or areas for improvement. By creating a physical representation of the building, contractors can visualize the construction sequence, plan logistics, and identify potential safety hazards. This simulation helps mitigate risks and optimize the construction process.

In conclusion, the use of 3D printed skyscraper models for feasibility testing is a valuable tool in the design and construction process of skyscrapers. By conducting wind tunnel experiments, structural analysis, material testing, and construction simulation, architects and engineers can refine their designs, optimize performance, and ensure the safety and feasibility of their projects.

9. Design validation

In the context of “3d printed skyscraper model,” design validation plays a crucial role in ensuring the accuracy, functionality, and safety of a skyscraper before its physical construction. 3D printed models provide architects and engineers with a tangible representation of their designs, allowing them to evaluate and refine their concepts before committing to large-scale construction.

- Physical Verification: 3D printed skyscraper models allow architects and engineers to physically verify their designs, identifying potential flaws or inconsistencies that may not be apparent in digital renderings. By holding a physical model in their hands, they can assess its proportions, scale, and overall form, ensuring that the design aligns with their intended vision.

- Structural Integrity: 3D printed models can be subjected to structural analysis and testing to assess their ability to withstand various loads and forces. This is particularly important for skyscrapers, which need to be able to withstand high winds, seismic activity, and other environmental factors. By testing the physical model, architects and engineers can identify and address any potential structural weaknesses, ensuring the building’s safety and stability.

- Construction Feasibility: 3D printed skyscraper models can help architects and engineers evaluate the feasibility of their designs from a construction standpoint. By creating a physical representation of the building, they can identify potential challenges or complexities that may arise during the construction process. This allows them to make necessary adjustments to their designs, ensuring that the building can be constructed efficiently and safely.

- Stakeholder Communication: 3D printed skyscraper models serve as valuable communication tools, enabling architects and engineers to convey their design intent more effectively to stakeholders, including clients, contractors, and regulatory authorities. By presenting a physical model, they can illustrate the building’s design, functionality, and structural integrity, facilitating better understanding and buy-in from all parties involved.

In conclusion, design validation through 3D printed skyscraper models is a critical step in the design process, providing architects and engineers with a tangible and reliable means to evaluate and refine their designs before construction begins. It contributes to the overall success and safety of skyscraper projects by ensuring accuracy, functionality, and structural integrity.

FAQs on “3D Printed Skyscraper Model”

This section addresses frequently asked questions about 3D printed skyscraper models, providing concise and informative answers to common concerns or misconceptions.

Question 1: What are the benefits of using 3D printed skyscraper models?

Answer: 3D printed skyscraper models offer numerous benefits, including high accuracy, customization capabilities, cost-effectiveness, time-saving, sustainability, enhanced collaboration, and educational value. They provide architects, engineers, and construction professionals with a powerful tool to visualize, test, and refine their designs, ultimately leading to better buildings.

Question 2: How accurate are 3D printed skyscraper models?

Answer: 3D printed skyscraper models are highly accurate, providing a precise representation of the final building. They are created using advanced 3D printing technology that ensures dimensional accuracy and intricate detailing. This accuracy is crucial for ensuring that the models can be used for detailed analysis, planning, and design validation.

Question 3: Can 3D printed skyscraper models be customized?

Answer: Yes, 3D printed skyscraper models can be customized to include specific details, such as windows, doors, balconies, and even interior layouts. This customization capability allows architects and engineers to explore different design options, test different configurations, and make informed decisions throughout the design and construction process.

Question 4: Are 3D printed skyscraper models cost-effective?

Answer: 3D printing technology offers a cost-effective way to create skyscraper models compared to traditional methods like handcrafting or CNC machining. The automated nature of 3D printing reduces labor costs, while the efficient use of materials minimizes material waste, resulting in overall cost savings.

Question 5: How can 3D printed skyscraper models save time?

Answer: 3D printing significantly reduces the time required to create skyscraper models. Unlike traditional methods, which can be time-consuming, 3D printing enables rapid prototyping and design iterations. This time-saving advantage allows architects and engineers to explore more design options, optimize their designs, and improve the overall efficiency of the design and construction process.

Question 6: What is the environmental impact of 3D printed skyscraper models?

Answer: 3D printing promotes sustainability in the creation of skyscraper models. It enables the efficient use of materials, reducing waste and minimizing the carbon footprin

t. Additionally, many 3D printing materials are recyclable, further contributing to sustainable practices in the construction industry.

In summary, 3D printed skyscraper models offer numerous advantages over traditional methods, making them an essential tool in the design and construction process. Their accuracy, customization capabilities, cost-effectiveness, time-saving benefits, sustainability, and educational value contribute to better decision-making, improved design outcomes, and overall success in skyscraper projects.

Transition to the next article section: The advancements in 3D printing technology continue to drive innovation in the construction industry, enabling the creation of increasingly complex and sustainable building models and structures.

Tips for Utilizing “3D Printed Skyscraper Model”

Harness the full potential of 3D printed skyscraper models with these practical tips:

Tip 1: Leverage High Accuracy for Detailed Analysis

Capitalize on the exceptional accuracy of 3D printed skyscraper models to conduct in-depth analyses. Utilize them for wind tunnel experiments, structural simulations, and material testing to gain valuable insights into the building’s performance and behavior.

Tip 2: Embrace Customization for Design Optimization

Maximize the customization capabilities of 3D printed skyscraper models to refine your designs. Explore various facade treatments, interior layouts, and structural configurations to optimize the building’s aesthetics, functionality, and structural integrity.

Tip 3: Leverage Cost-Effectiveness for Iterative Design

Utilize the cost-effectiveness of 3D printing to create multiple iterations of your skyscraper model. This enables you to experiment with different design concepts, test various scenarios, and make informed decisions throughout the design process.

Tip 4: Utilize Time-Saving Benefits for Efficient Design

Capitalize on the time-saving advantages of 3D printing to accelerate your design process. Rapidly create physical models for visualization, design validation, and stakeholder communication, saving valuable time and resources.

Tip 5: Enhance Sustainability for Environmentally Conscious Design

Embrace the sustainability benefits of 3D printing by using eco-friendly materials and minimizing material waste. Create skyscraper models that not only meet design requirements but also contribute to environmentally responsible construction practices.

Tip 6: Foster Collaboration through Model Sharing

Facilitate effective collaboration by sharing 3D printed skyscraper models with stakeholders. Enhance communication, improve feedback mechanisms, and ensure that all parties are aligned on the design intent.

Tip 7: Utilize Educational Value for Knowledge Dissemination

Harness the educational value of 3D printed skyscraper models to teach architectural concepts and principles. Use them as visual aids in classrooms, workshops, and exhibitions to foster a deeper understanding of skyscraper design and construction.

Tip 8: Stay Informed about Technological Advancements

Continuously monitor advancements in 3D printing technology to stay abreast of the latest innovations. Explore emerging materials, improved printing techniques, and novel applications to push the boundaries of skyscraper model creation.

Incorporating these tips into your workflow will maximize the benefits of 3D printed skyscraper models, enabling you to design, analyze, and optimize your projects with greater efficiency, accuracy, and innovation.

Conclusion

3D printed skyscraper models have revolutionized the design and construction industries, providing architects, engineers, and construction professionals with a powerful tool to visualize, test, and refine their designs. These models offer numerous advantages, including high accuracy, customization capabilities, cost-effectiveness, time-saving, sustainability, enhanced collaboration, and educational value. By leveraging 3D printing technology, we can create increasingly complex and realistic skyscraper models that contribute to better decision-making, improved design outcomes, and overall success in skyscraper projects.

As we continue to advance 3D printing technology, we can expect even more innovative and groundbreaking applications in the field of skyscraper design and construction. These models will play a crucial role in shaping the future of our cities, enabling us to build taller, more sustainable, and more resilient skyscrapers that meet the ever-evolving needs of our society.